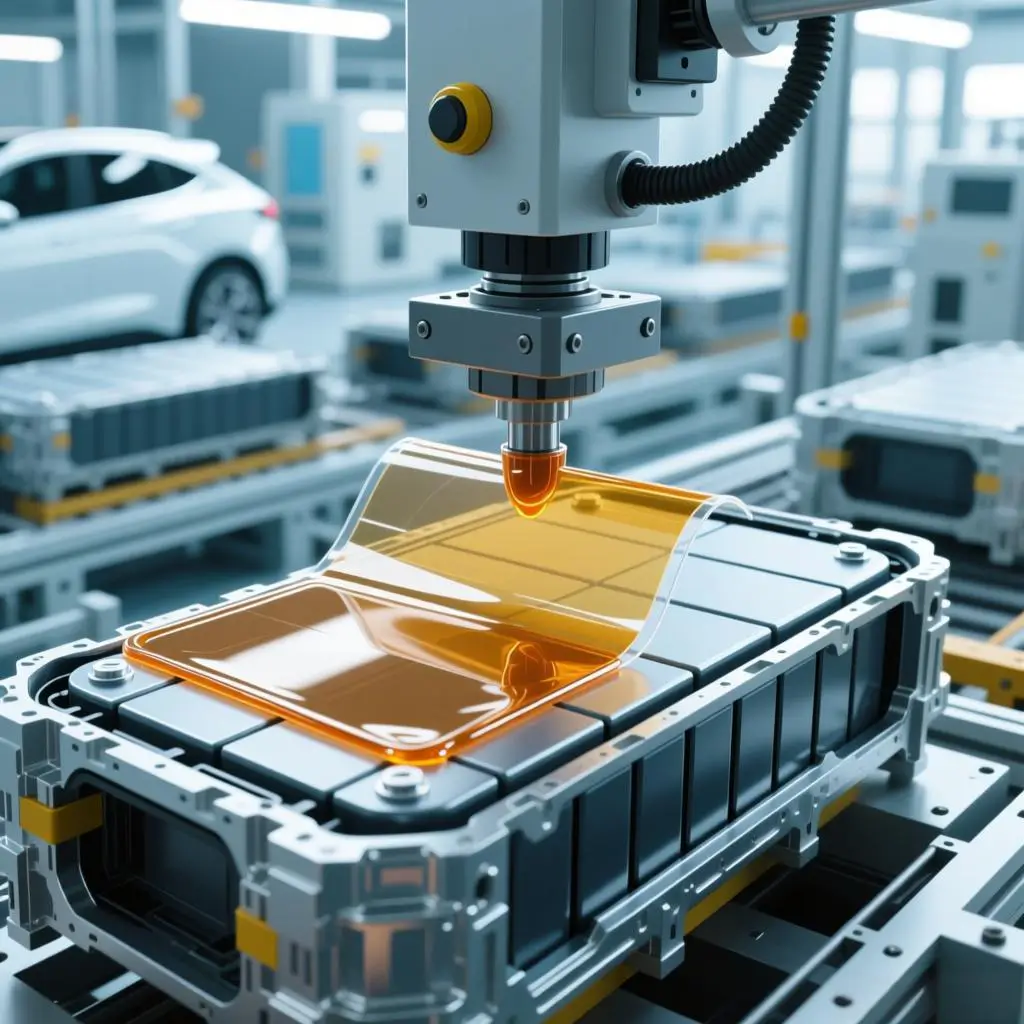

Improved production efficiency

The TPU hot melt adhesive film uses the hot melt process, which reduces the steps required for traditional manual sewing and glue bonding. During production, only simple heating and pressing operations are needed to achieve tight bonding between fabrics, greatly improving production efficiency and reducing costs.

Improved product quality

By using TPU hot melt adhesive film, fabrics can be quickly bonded without affecting their appearance, preventing issues such as stretching and wrinkling that might occur with traditional sewing methods. This provides higher aesthetics and quality assurance for products like clothing and footwear.